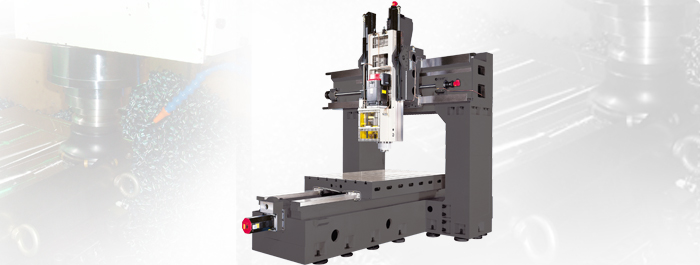

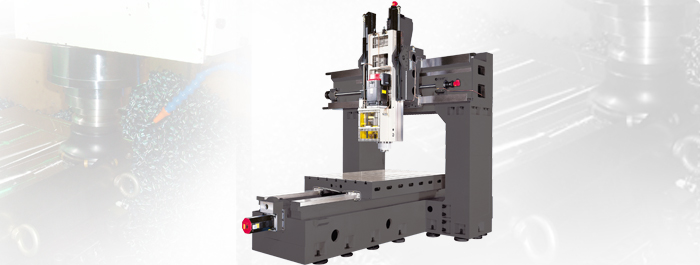

Double column machining center

High efficiency machining

Rigid heavy cutting

Moving beam/ fixed beam 5-face machining

High performance 5-axis machining center

Gantry type Machining center

Vertical Machining Center

Portal Milling Machine

-

- MB series machines, with typical VW products features of rigid structure and high precision, are designed with box ways with hand scrapping, cutting vibration adapting, and precise power transmission to get the efficient, rigid and accurate cutting.

- Wide base with solid columns and beam, providing the best structure stiffness to ensure the best geometric accuracy of 3-axis travel.

- Full casting components with square guideways coated with precision scrapping to ensure the best stiffness and low friction. (MB/MF)

- One piece casting for gear head transmission and headstock. Z-axis is at the symmetrical position of spindle motor, offering accuracy and precision with micro smooth movement. (MS/MB/MF/MN/MH)

- Using Japan made JIS0 gears for gear head to get the advantages of high rigidity, high precision, and low noise.

- Twin Hydraulic cylinders plus pressured nitrogen accumulator balancing design provides smooth & accurate feeding performance. Cylinders are self-alignment, balancing force is set optimally by adjustable pressure valve. (MS/MB/MF/MH)

- square guideway : Direct lubrication offering to the gibs on 3 axes box ways ensures 100% lubrication certainness. (MB/MF)

- Hanged & swivel able operation panel & Multi layers front door offer a friendly and safe operation interface. (MS/MB/MF/MN/MH)

- Tool Magazine, side mounted on column, makes the machine with compact design. Cam type ATC has the tool-to-tool changing in 3 sec. Random setting and Large Tool Management help to get the best operation efficiency. (MB/MF/MS/MN/MH)

-

| 機型 |

單位 |

MB-2016 |

MB-2516 |

MB-3016 |

MB-2020 |

MB-2520 |

MB-3020 |

MB-4020 |

| 行程 |

| X軸行程 |

mm |

2,000 |

2,500 |

3,100 |

2,000 |

2,500 |

3,100 |

4,100 |

| Y軸行程 |

mm |

1,600 |

1,600 |

1,600 |

2,000 |

2,000 |

2,000 |

2,000 |

| Z軸行程 |

mm |

800/1,020(選購) |

| 工作台 |

| 工作台面積 |

mm |

2,000

×

1,300 |

2,500

×

1,300 |

3,100

×

1,300 |

2,000

×

1,700 |

2,500

×

1,700 |

3,100

×

1,700 |

4,100

×

1,700 |

工作台

最大載重 |

kg |

8,000 |

9,000 |

10,000 |

9,000 |

10,000 |

11,000 |

12,000 |

| 主軸 |

主軸馬達

(連續/30分鐘額定) |

kW |

18.5/22(22/26 選購) |

主軸 speed

(二段齒輪箱軸) |

rpm |

4,500/6,000(選購) |

主軸 speed

(皮帶式) |

rpm |

8,000/10,000(選購) |

| 主軸孔錐度 |

|

BT50/CAT50 |

| 進給 |

| 切削進給速率 |

mm/min |

1-7,000 |

| 快速進給速率 |

m/min |

XYZ:15 |

XYZ:15 |

XY:12

Z:15 |

XYZ:15 |

XYZ:15 |

XYZ:15 |

XY:12

Z:15 |

| 其他 |

| 機械淨重 |

kg |

21,500 |

24,500 |

27,500 |

23,500 |

26,500 |

29,500 |

32,500 |

| 機械毛重 |

kg |

25,000 |

28,000 |

32,000 |

27,000 |

30,000 |

34,000 |

35,000 |

-

標準功能與附件

- Fanuc 0i MD控制器

- 硬軌機頭4,500 rpm兩段齒輪變速主軸

- 主軸齒輪及冷卻系統

- 雙油壓缸及氮氣輔助配重系統

- X軸導螺桿防震支撐裝置(4m以上)

- 32刀及刀臂式自動換刀系統

- 中央集中自動進給潤滑裝置

- 三軸潤滑油獨立收集裝置

- 全封式防護罩(不含頂面)

- 工作燈

- 三色警示燈

- 主軸錐孔清潔吹氣

- 分離式手搖輪

- 操作側清潔水槍及空氣接口

- RS232/RJ45介面

- 絕對式位置檢出器

- 喬崴進FX系列人機介面

- 切削液系統(環狀及噴管) (不適用於AC介面)

- 電器箱熱交換器

- 工作台側螺旋式切削輸送器

- 鏈式鐵屑輸送機 conveyer

- 地基墊塊及調整螺栓

- 工具箱

- 操作維修手冊及控制電路資料

選購功能與附件

- 6,000 rpm 兩段齒輪變速主軸

- 8,000 rpm/10,000 rpm 皮帶式主軸

- 40刀刀庫

- 油路刀把介面

- 主軸中心出水系統

- 三軸中空螺桿及冷卻系統

- HEIDENHAIN全閉環光學尺

- 立柱加高200/300/400 mm

- 副工作台

- 油水分離裝置

- 油霧冷卻裝置

- 旋轉工作台

- 預留第四軸介面

- 三軸手搖輪

- 自動刀長量測

- 自動工件量測

- 手動90度頭/延長頭/萬向頭

- 變壓器

- 集屑桶