VISION WIDE TECH CO., LTD.

- Address: No. 1126-2, Bishan Rd., Caotun Township, Nantou 54258, Taiwan

- Tel: 886-49-2338888

- Fax: 886-49-2330083

- mail: info@visionwide.com.tw

- Privacy Policy

- 2018 Vision Wide Tech All Right Reserved

Industries Applications - Mold

- Home

- Solution

- Industries

- Mold

-

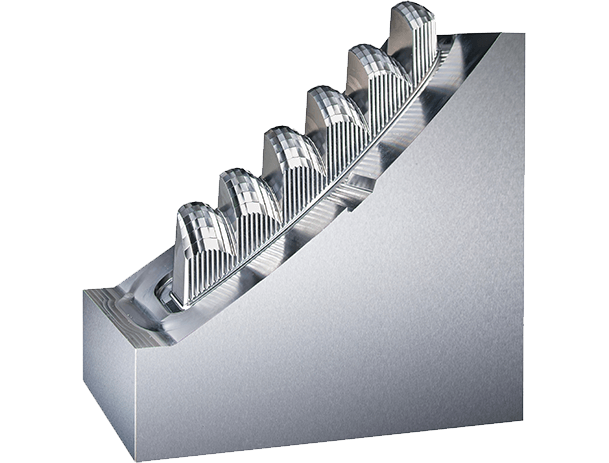

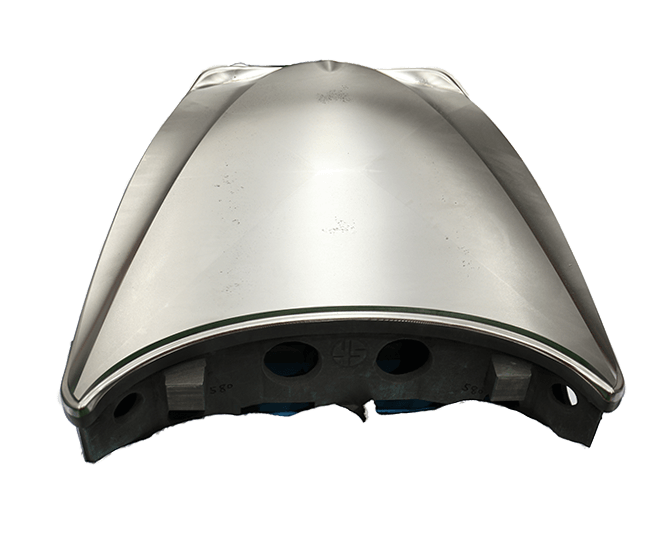

Automobile Light Mold

- Model:ASM

- Material:2311 Die steel

- Size:L360 x W160 x H360mm

- Linear project cutting

- Multi inclined plan, oblique angle cutting, improve machining efficiency

- Surface roughness : Ra0.4µm

- 0.04mm contour accuracy

-

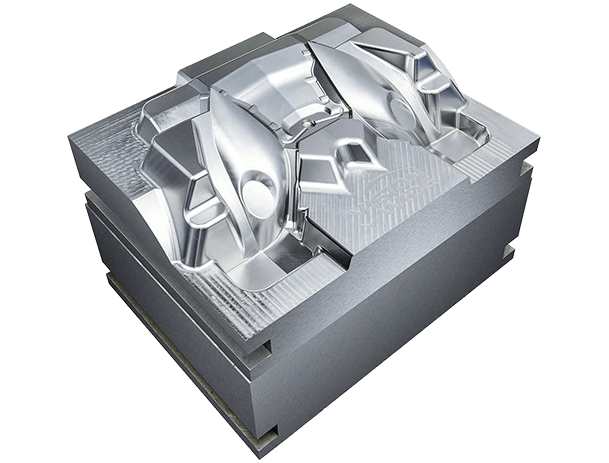

Headlight Mold

- Model:SE/ GS/ GSF

- Material:P20 Die Steel

- Size:L800 x W550 x H250mm

- 0.2G high acceleration mold finishing

- D25 High feed rough machining: F10,000 mm/min

- D10R5 High speed mold surface finish machining:S12,000 rpm, F4,000 mm/min

- Surface roughness : Ra0.4μm

- 0.04 mm high contour accuracy

-

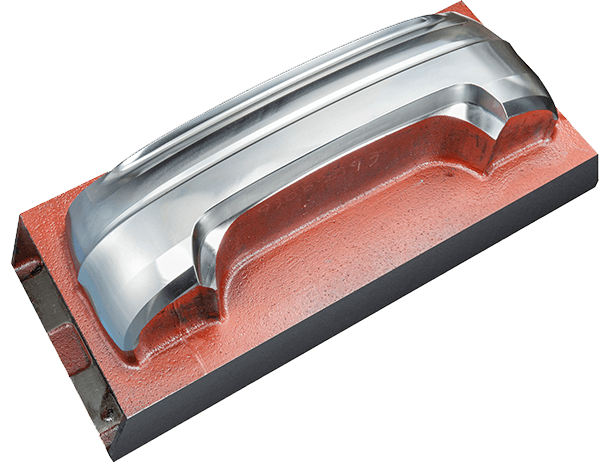

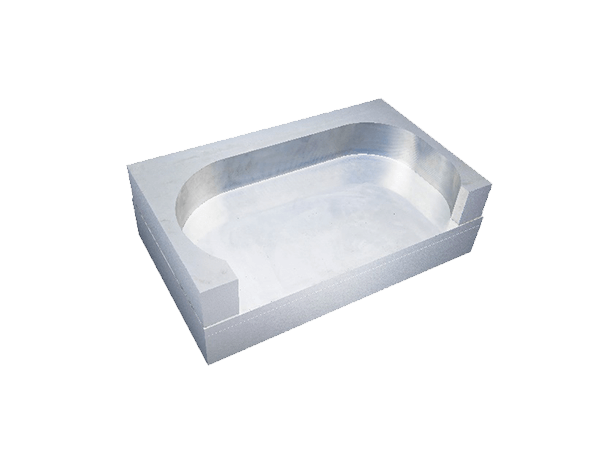

Bumper Mold

- Model:SF

- Material:FC300

- Size:L1,000 x W400 x H350mm

- Long spindle nose is the benefit to enhance the tool rigidity and reduce the cutting vibration.

- D20R10 ball end tool reciprocating projection machining

- Pitch:0.5mm

- Spindle speed : 12,000 rpm

- Feed rate : 5,000 mm/min

-

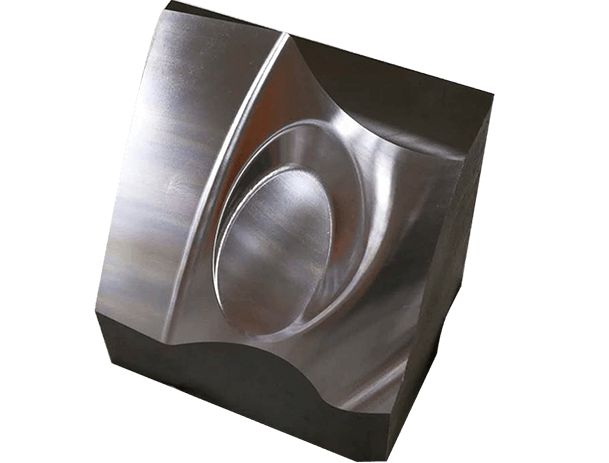

Automotive Reflector Light Core

- Model:SE/GS series

- Material:NAK80 die steel

- Size:160 x 160 x 100 mm

- Surface roughness : Ra 0.4μm

- Contour accuracy 0.02 mm

- D3R1.5 ball end machining

- Spindle speed : 12,000 rpm

- Feed rate : 1,500 mm/min

-

Headlight Cavity Finishing

- Material:Alloy steel

- Size:L151mm x W105mm x H155mm

- Surface height difference:103mm

- Surface roughness:Ra 0.8 mm

- Long tool machining:tool length 262mm

- Tool:D12R6 Hard ball end

- Tool path :Zig-zag contour processing

- Spindle speed:8,000 rpm

- Feed rate:2,000mm/min

- Total machining time:1hr 58min

-

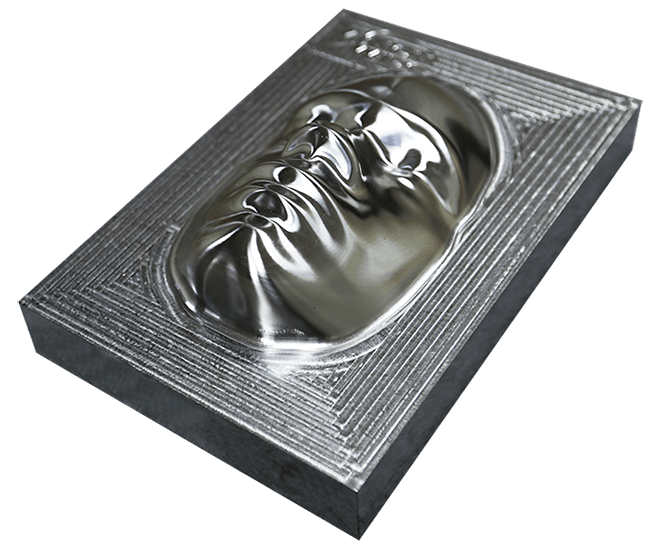

Mask Core Mold

- Model : F series

- Material : S45C

- Size:300 x 200 x 100 mm

- High speed and high accuracy mold machining

- High contour accuracy

- 98.5% point error < 0.02mm

- 85.8% point error < 0.012mm

- D12R6 ball end tool

- 45° Project zig-zag cutting

- Spindle speed : 10,000 rpm

- Feed rate : 4,000 mm/min

-

Benz Mold

- Material:NAK 80 die steel

- 0.2G high acceleration mold machining

- High federate rough machining:D25、F10,000mm/min

- High speed surface finish machining:F4,000mm/min

- Surface roughness : Ra 0.4μm

- 45°Project zig-zag cutting

- Spindle speed : 12,000 rpm

- Feed rate : 4,000 mm/min

-

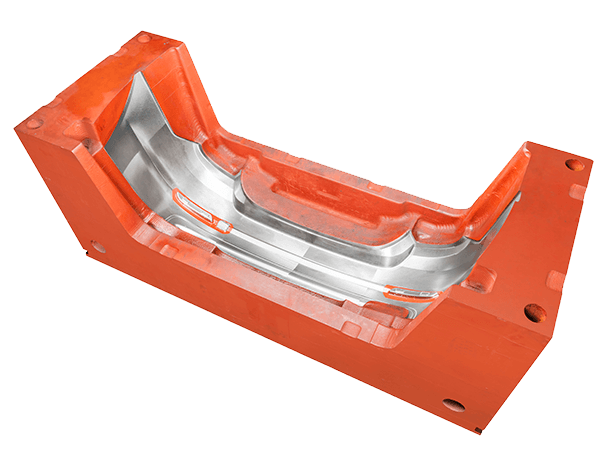

Bumper Mold

- Model : FA

- Material:FC300

- Size:900 x 2300 x930mm

- 5-axis synchronized machining, 30% machining efficiency improved.

- Long spindle nose enhance the tool rigidity and reduce the cutting vibration.

- D20R10 ball end tool

- Project zig-zag cutting

- Spindle speed : 8,000 rpm

- Feed rate : 5,000 mm/min

-

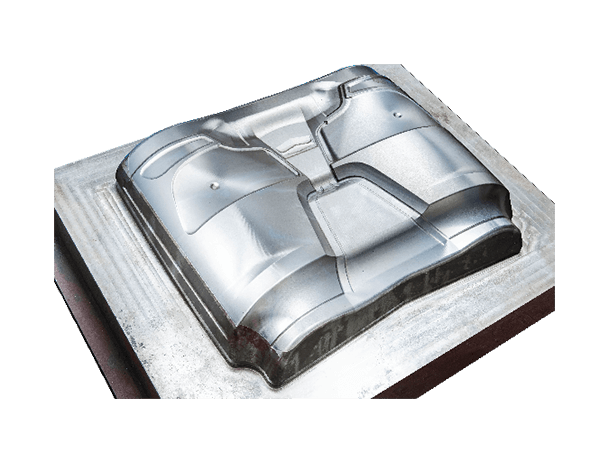

Automotive Sheet Metal Mold

- Model : FA

- Material:FC300

- Size:2300 x 1600 x 250mm

- 0.2G high acceleration mold machining

- High feedrate die surface finishing : F7,000mm/min

- High clear machining path

- Total finish time:6.3hr

- D25 ball end tool

- 45°Project zig-zag cutting

- Spindle speed : 8,000 rpm

- Feed rate : 7,000 mm/min

-

Engine Hood Mold

- Material:FC300

- Size:2,000 x 1,600 x 500mm

- 10 m/min high speed machining

- 0.3G high acceleration machining

- Total finish time:5.2 hrs.

- D25 ball end tool

- Pitch:0.5mm

- Surrounding isometric machining

- Spindle speed : 12,000rpm

- Feed rate : 5000 mm/min

-

Mold Verification Workpiece

- Model:GS/ SE

- Material:2311

- Size:150 x 60 x 30 mm

- D4R2 ball end tool finish

- Surround interpolation milling without tool mark

- Precise Z-reversed cutting with sharp edges and corners

- Surface roughness : Ra 0.8µm

-

Car Stamping Mold

- Material:P20

- Size:L640mm x W505mm x H270mm

- Finish Tool:D16R8 Ball End

- Finish Pitch:0.3mm

- Tool Path:45angle project zig-zag cutting

- High feed rate finishing of mold surface F3000→F5000

- High acceleration cutting 0.05G→0.2G

- Total finishing time reduce 20%

- 6hr08min→4hr54min

- Surface roughness:Ra 0.6μm

- Spindle Speed:15,000 rpm

- Feed rate:5,000mm/min

-

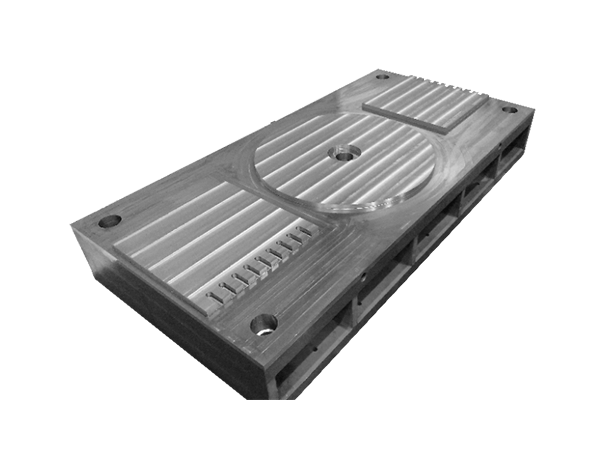

Mold Base High Feedrate Machining

- Model : SE / GS

- Material : S45C

- Size:800 x 500 x 250mm

- Vc 220 m/min

- 10 m/min High federate machining

- Boring positioning accuracy 0.006 mm (Pitch 400x700mm)

- Spindle speed : 2,000rpm

- D40 R1 High feed tool

-

High Positioning Inspection Workpiece

- Model:F Series/ BM/ XM/ XML/ XMF

- Material: FC30

- Size:2,000 x 1,000 x 200mm

- 1.8x0.8 m high position accuracy of boring hole:0.02mm

- D900 Circular interpolation machining Circularity:0.02mm

- 400x400mm Squareness:0.01mm

-

24m High Speed Machining Workpiece

- Material:Al6061

- 24 m high speed machining

- Equal TEA tool path

- 70 mm long tool machining

- Tool:D25R1 end mill

- Spindle speed:10,500rpm

- Feed rate : 24,000 mm/min

-

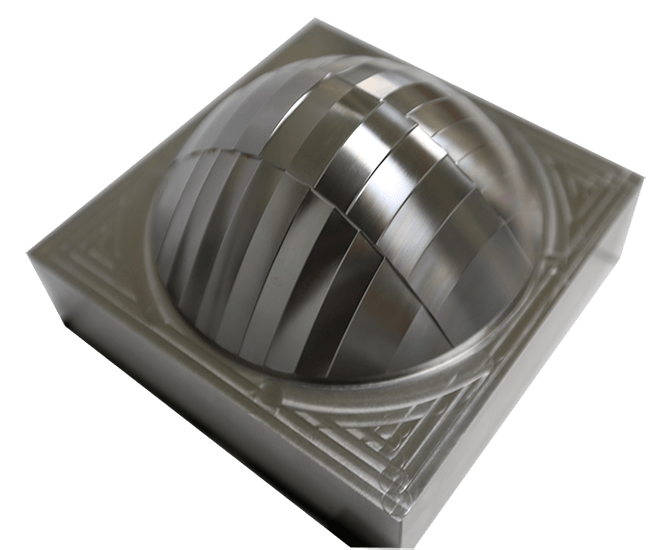

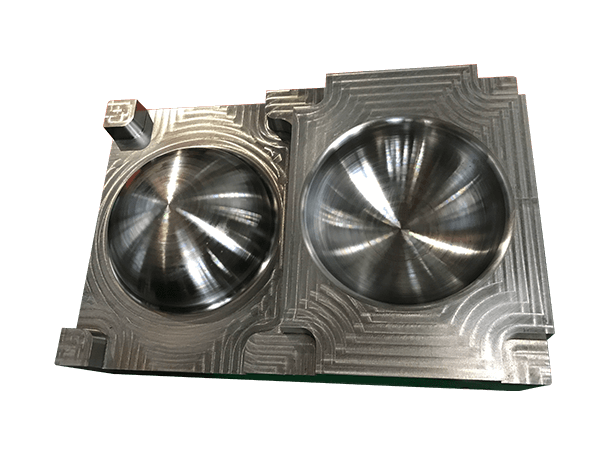

Ball Mold

- Model:GS/ SE

- Material:2311 Die steel

- Size:300 x 200 x 150 mm

- D12R6 ball end tool

- Circular interpolation milling without tool mark

- Surface roughness : Ra 0.4µm

-

Deep cavity mold

- Model:SM

- Material:P20 die steel

- Short-distance surround machining, high-precision feed control

- Four-quadrant commutation without chatter marks

- Simultaneous machining to maintain high finish, no over-cutting, no chatter marks

- Plane accuracy:-0.011 ~ 0.006mm

- Spherical accuracy:-0.012 ~ 0.006mm

- D20R1 end mill finishing

- Spindle speed : 3,500rpm

- Feed rate : 5,200mm/min

-

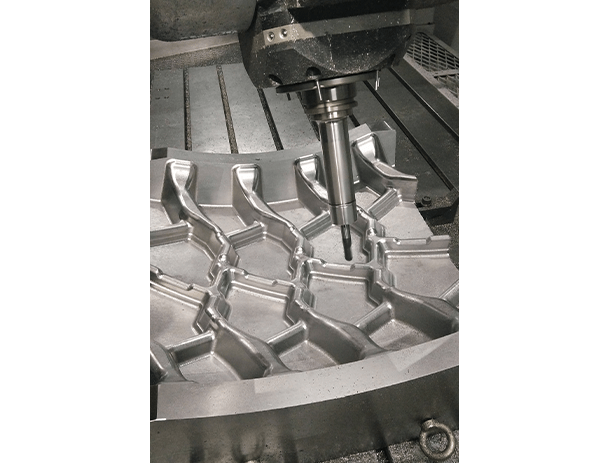

TIRE Mold (Segment Type)

- Model:FA

- Material:S45C

- Size:660 x 600 x 260mm

- Corner smooth flow cut via 5-axis synchronized machining.

- D25 High feed rough cutting: F10,000

- F3,000 R6 finishing

- Multi-axis project machining

- Spindle speed : 15,000 rpm

- Feed rate : 4,000 mm/min

-

Ball Shape

- Model :FA / GSF

- Material :Al6061

- Size:D280 mm

- 5 axis synchronized machining without deceleration

- High synchronized feedrate, F2,000

- High servo control

- Each axis feed > F10,000mm/min

- Finishing Time : <20min

- Surface accuracy :<±0.02mm

-

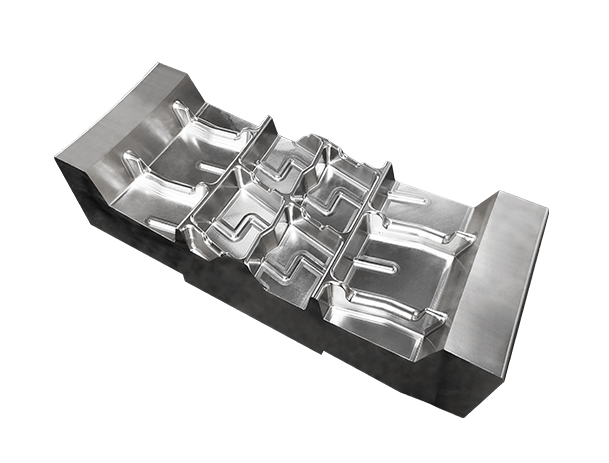

Tire Mold (Segment type)

- Material:P20 Die Steel

- L310 x W131 x H95mm

- One-step machining:High-feed rough machining & High-speed mold machining & 5-axis synchronized machining corner flow cut

- High-feed rough machining : F7,200mm/min, Ap0.6mm

- High-speed mold machining : Ra<0.5μm

- 5-axis synchronized R0.5mm machining, effectively reducing tool length and avoiding interference.